caco3 masterbatch pellet machine

Basic Info

Model No.: TSE-75 masterbatch extruder

Product Description

1.High speed steel screw

2.500~1000kg/h

3.easy operation

4.CE;ISO9001

pp pe caco3 Pelletizing Machine PP PE filler masterbatch 85%caco3 extruder

85% CaCO3 masterbatch

85% CaCO3 masterbatch  Customer test &acceptance machine on site

Customer test &acceptance machine on site

Technical data for all kind of extruder

Technical data for all kind of extruder Mode | Diameter (mm) | L/D | Screw rotary speed (r/min) | Motor power (kw) | Torque (N.m) | Capacity (kg/h) |

TSE-20 | 22 | 32-44 | 600 | 5.5 | 43 | 1-10 |

TSE-30A | 31 | 32-48 | 500 | 11 | 105 | 5-30 |

TSE-30B | 600 | 15 | 119 | 5-40 | ||

TSE-40A | 41 | 32-52 | 600 | 15 | 119 | 65-110 |

TSE-40B | 400 | 22 | 263 | 90-150 | ||

TSE-52B | 51.5 | 32-64 | 600 | 75 | 597 | 225-250 |

TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 250-300 |

TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 350-550 |

TSE-75D | 71 | 32-64 | 600 | 220-250 | 1990 | 500-1000 |

TSE-95A | 93 | 32-64 | 500 | 250 | 2387 | 600-1000 |

TSE-95B | 93 | 32-64 | 600 | 315 | 2506 | 800-1200 |

TSE-135 | 133 | 32-64 | 500 | 750 | 7162 | 1500-2250 |

2.The feeding system Metering feeders are equipped with single screw,twin screw,hollow screw,forced-feeding,side feeding,liquid-adding system,etc

2.The feeding system Metering feeders are equipped with single screw,twin screw,hollow screw,forced-feeding,side feeding,liquid-adding system,etc  3.Screw The screw elements and then kneading blocks are designed accurately,by precise processed, agile combination,with interchangeability, which can fulfill efficient self-cleaning,transmission,compounding,pressure-forming. The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treament.

3.Screw The screw elements and then kneading blocks are designed accurately,by precise processed, agile combination,with interchangeability, which can fulfill efficient self-cleaning,transmission,compounding,pressure-forming. The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treament.  4.The barrel Euro-style rectangle barrel,reflux refrigeration is optimized and disposed,which makes temperature difference in C areas smaller According to the material and special techinics demands,the material of cylinder can use high quality nitrided steel,corrosion proof or antifriction with corresponding process

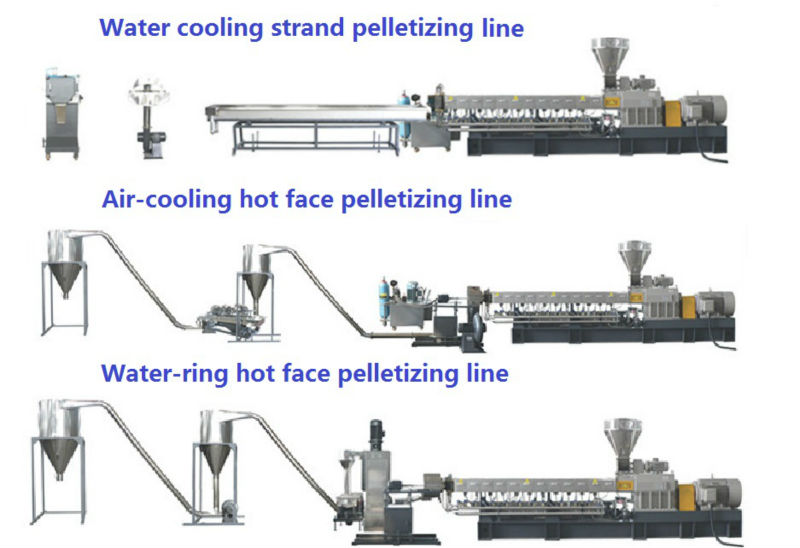

4.The barrel Euro-style rectangle barrel,reflux refrigeration is optimized and disposed,which makes temperature difference in C areas smaller According to the material and special techinics demands,the material of cylinder can use high quality nitrided steel,corrosion proof or antifriction with corresponding process  5.The heater Innovated design of heater tightened style insures high efficiency of heat transfer and high longervity of heater. 6.Pelletizing Variou modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelleting,etc. Recommand with air-cooling Pelletizing System for PE filler masterbatch 85%caco3 extruder Service System:

5.The heater Innovated design of heater tightened style insures high efficiency of heat transfer and high longervity of heater. 6.Pelletizing Variou modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelleting,etc. Recommand with air-cooling Pelletizing System for PE filler masterbatch 85%caco3 extruder Service System:  Packaging&Delivery:

Packaging&Delivery:  Please feel free to ask me, if there are any question.Mr.Leo is here waiting for your inquiry.Skyp(Leo.nanjing) +86 18251933105 Contact us if you need more details on Caco3 Masterbatch Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Caco3 Pellet Machine、Caco3 Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Please feel free to ask me, if there are any question.Mr.Leo is here waiting for your inquiry.Skyp(Leo.nanjing) +86 18251933105 Contact us if you need more details on Caco3 Masterbatch Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Caco3 Pellet Machine、Caco3 Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : co-rotating twin screw extruder > Other twin screw extruder

Premium Related Products