Ce Certificate Twin Screw Extruder Barrel

Basic Info

Model No.: TD-65

Product Description

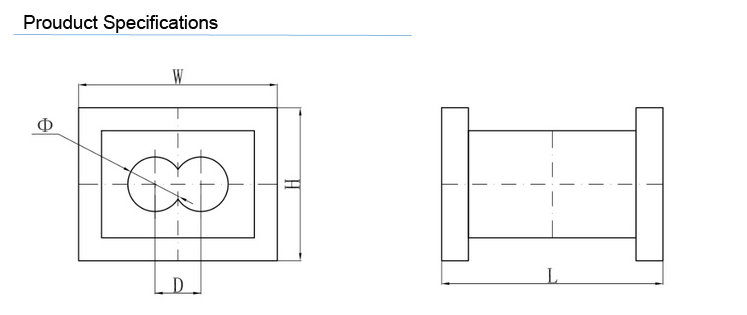

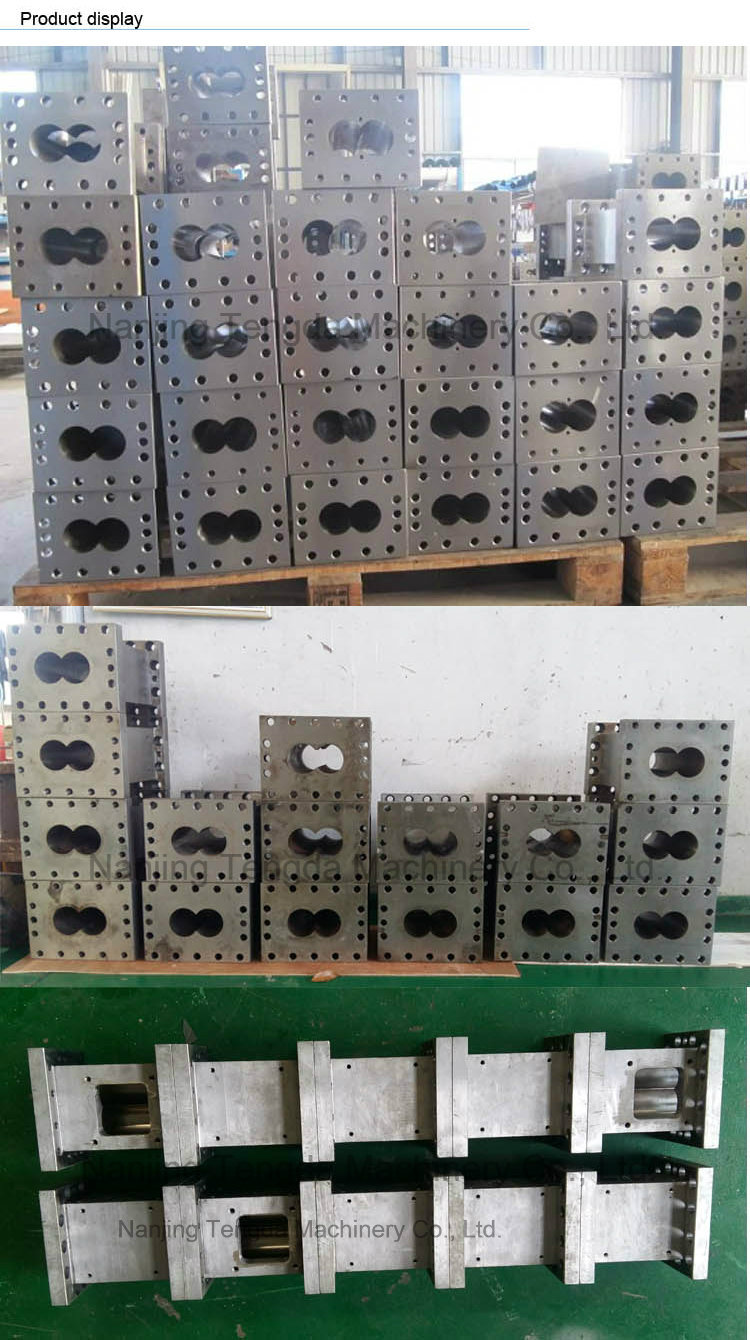

Model NO.: TD-65 Technics: Plastic Granules Application: Co-Rotating Twin-Screw Extruder Color: Plain Color of Stee Barrel Structure: Modular Barrel Structure Treatment: Heating Treatment Plpastic Processed: PP PE HDPE Lhdpe Ect Specification: W6Mo5Cr4V2 or38CrMoAl Standard: Ce&ISO Material: Stainless Steel Screw Type: Parallel Screw Barrel: Long-Term Available Screw Design: Double-Screw Product Type: Extrusion Trademark: TENDA Origin: Jiangsu, China CE Certificate Twin Screw Extruder Barrel

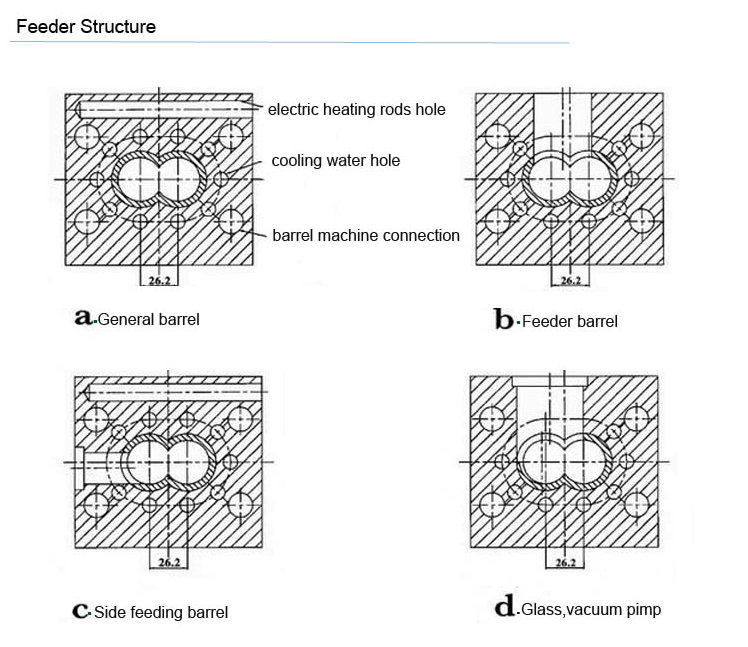

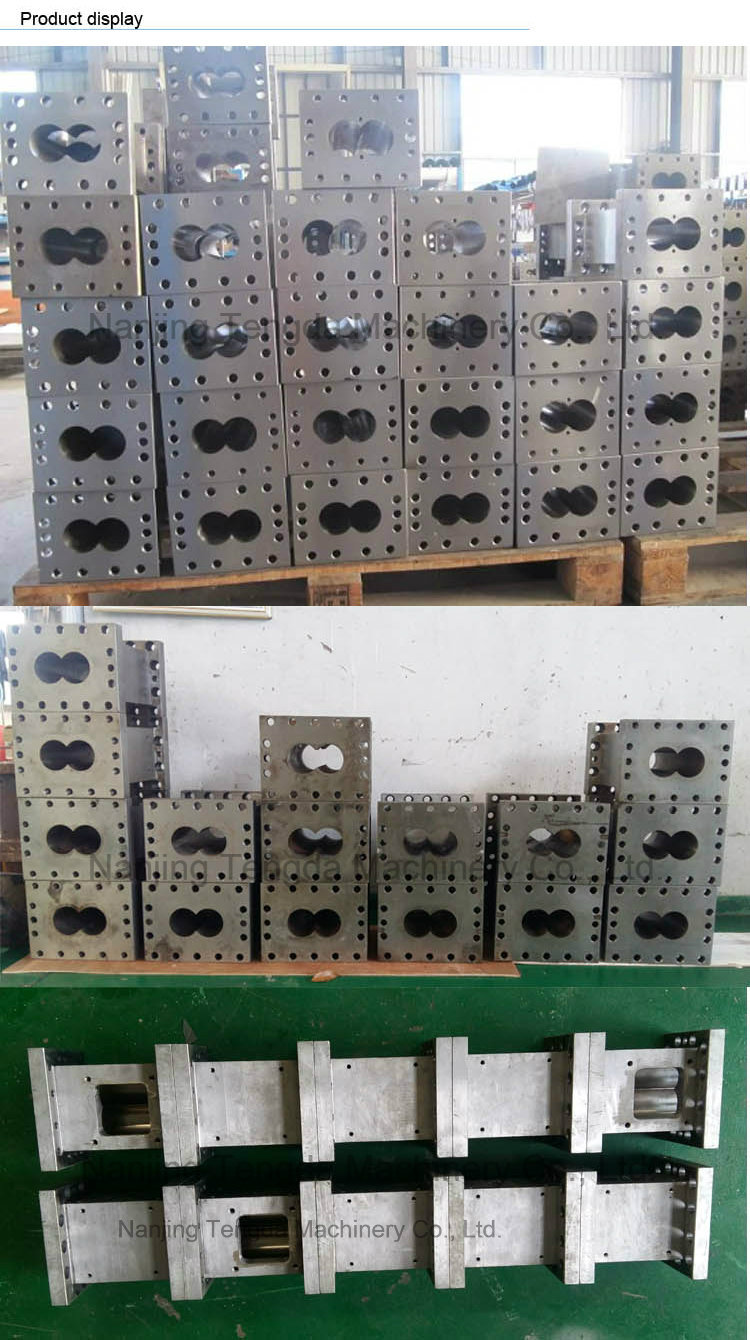

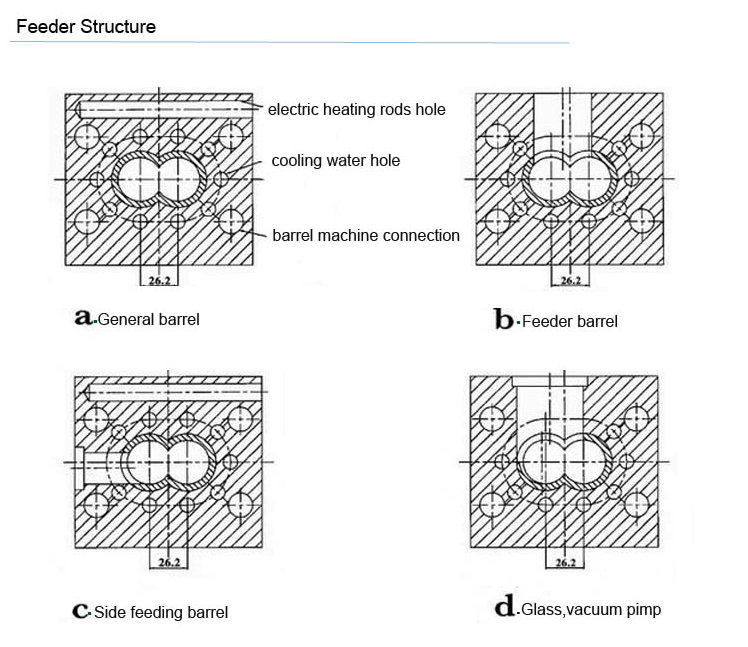

Description: Using machining center finishing, reasonable processing technology, advanced testing equipment, to ensure that the processing accuracy of each product.

The flexible modular principle is realized with screw barrel sections from the wide Range ofdifferent designs possible. Fast, intensive and uniform heating ofthe screw Barrel section is ensured by electrical heaters. The barrel sections are cooled with Water, by means ofan internal bore system, with bores arranged close to the inside Barrel wall.

Barrel Type-by appearance

1.Close tube

2.open tube

3.side-feeding closed barrel

4.Side-feeding open barrel

5.Extruding barrel

6.Liquid filling cylinder

Barrel Type -liner

1.Type"C"barrel

2.Overall liner barrel

3.Bareel without liner

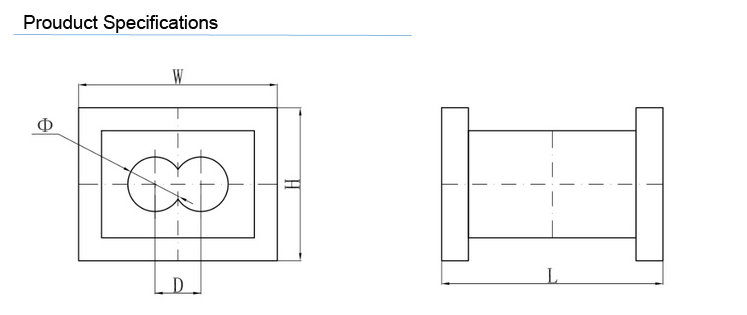

4.Prouduct specifications

Barrel Type -materials

1.Nitriding Steel Barrel

2.Binetal Alloy Barrel

3.316L Stainless Steel Barrel

Packaging for exports:

Package: Wooden case or Using Anti-rust oil processing, then use stretch film cover extruder against moisture damage.

Shipping: By sea or By express

Contact us

FAQ Q: Are you trading company or manufacturer?

A: We are factory.We have the technical production team,and the workers are all very experienced.

Q: Why choose you?

A:You can get a very fair price from us and our price can make you beat your competitors in the marke

Q: What kind of certification do you have?

A: Our products have obtained ISO9001 and CE certification,the quality can be guaranteed.We focus on the field of Extrusion Machine,and aim to be the best manufacturer of this field.

Q:What's the payment?

A:L/C, T/T, Western Union, Paypal, Money Gram. Contact us if you need more details on Barrel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Extruder、Twin-Screw. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Standard Barrel Parameter Table (selection table) | |||

| Model | Size(mm) W*H*L | Hole Diameter(mm) | r Distance(mm) |

| TD-20 | 115*105*132 | Φ23 | 18.4 |

| TD-30 | 135*115*120 | Φ30.6 | 26 |

| TD-35 | 140*120*140 | Φ36 | 30 |

| TD-36 | 160*140*150 | Φ36 | 30 |

| TD-40 | 175*145*160 | Φ41.6 | 34.5 |

| TD-50 | 190*150*190 | Φ51 | 42 |

| TD-52 | 200*155*210 | Φ52 | 43 |

| TD-53 | 210*160*220 | Φ53.3 | 48 |

| TD-58 | 220*175*240 | Φ58 | 48 |

| TD-60 | 210*170*240 | Φ60 | 52 |

| TD-65 | 210*170*240 | Φ63 | 52 |

| TD-75 | 260*200*290 | Φ71.8 | 60 |

| TD-85 | 280*215*320 | Φ81.9 | 67.8 |

| TD-92 | 310*240*360 | Φ92 | 78 |

| TD-95 | 310*240*360 | Φ94 | 78 |

| TD-110 | 330*240*420 | Φ109 | 91.5 |

| TD-125 | 390*290*500 | Φ125 | 98 |

| TD-135 | 370*300*410 | Φ134 | 110 |

Description: Using machining center finishing, reasonable processing technology, advanced testing equipment, to ensure that the processing accuracy of each product.

The flexible modular principle is realized with screw barrel sections from the wide Range ofdifferent designs possible. Fast, intensive and uniform heating ofthe screw Barrel section is ensured by electrical heaters. The barrel sections are cooled with Water, by means ofan internal bore system, with bores arranged close to the inside Barrel wall.

Barrel Type-by appearance

1.Close tube

2.open tube

3.side-feeding closed barrel

4.Side-feeding open barrel

5.Extruding barrel

6.Liquid filling cylinder

Barrel Type -liner

1.Type"C"barrel

2.Overall liner barrel

3.Bareel without liner

4.Prouduct specifications

Barrel Type -materials

1.Nitriding Steel Barrel

2.Binetal Alloy Barrel

3.316L Stainless Steel Barrel

Packaging for exports:

Package: Wooden case or Using Anti-rust oil processing, then use stretch film cover extruder against moisture damage.

Shipping: By sea or By express

Contact us

FAQ Q: Are you trading company or manufacturer?

A: We are factory.We have the technical production team,and the workers are all very experienced.

Q: Why choose you?

A:You can get a very fair price from us and our price can make you beat your competitors in the marke

Q: What kind of certification do you have?

A: Our products have obtained ISO9001 and CE certification,the quality can be guaranteed.We focus on the field of Extrusion Machine,and aim to be the best manufacturer of this field.

Q:What's the payment?

A:L/C, T/T, Western Union, Paypal, Money Gram. Contact us if you need more details on Barrel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Extruder、Twin-Screw. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Spare Parts > Screw and barrel

Premium Related Products

Other Products

Hot Products

Twin Screw Extruder Machine for 3D Printer Filament MaterialsNylon Extruder Machine with Air Cooling Hot Face Pelletizing SystemHigh Filler Formulation Twin Screw ExtruderTsh-75/Se-180 Water Ring Pelletizing System Twin Screw ExtruderPP,PE,PS+starch/PE,EVA,ABS+carbon black filling masterbatch pelletizer extruderHigh quality and Standard Twin Screw Extruder Screw ElementHS high quality TSE-65 twin-screw parallel co-rotating extruderUnderwater Extrusion Line PVC Masterbatch Making MachinePET Plastic Recycled Granules For Pelletizer Extrusion LineHS series SP Two-stage Compounding Extruder Pelletizing SystemSHJ-65 Co-rotating Twin-screw Extrusion machinery for pelletizingPlastic Pelletizing Line Horizontal Water Ring Extrusion MachineryTSE-65D Co-rotating Twin Screw Extruder in Air-cooling Extrusion LinePlastic Recycling Compound Masterbatch Filler Machine PriceMini Plastic Masterbatch Granulator Single Screw Extruder MachineMini PPR Pipe Plastic Compound Extruder Machine For Sale Price