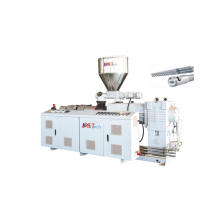

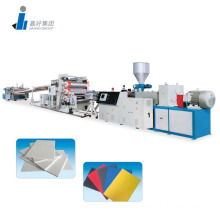

Waste Plastic Recycling Pelletizing Machine

| Unit Price: | 10000~28000 USD |

|---|---|

| Min. Order: | 1 Set/Sets |

| Packaging: | Packing film and wooden box |

|---|---|

| Productivity: | 100-1100kg/h |

| Brand: | KEHAO |

| Transportation: | Ocean,Land,Air,s |

| Place of Origin: | China |

| Supply Ability: | 30sets/month |

| Certificate: | CE |

| Port: | Ningbo Port,Shanghai Port |

Click on the follow link to find out more information: https://www.khplasticmachinery.com/hdpe-ldpe-plastic-film-pelletizing-machine/

Company Info

- Company Name: Zhejiang Kehao Plastic Machinery Co., Ltd.

- Representative: Mingju Hou

- Product/Service: Plastic Granulator , Plastic Pelletizer , Waste Plastic Film Recycling Machine , Plastic Granules Cutting Machine , Plastic Recycling Machine , Plastic Pellets Making Machine

- Capital (Million US $): $100Million

- Year Established: 2017

- Total Annual Sales Volume (Million US $): Above US$100 Million

- Export Percentage: 21% - 30%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 6

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 41 -50 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No.88 Jinshidi Road.Langxia Streed.Yuyao City.Zhejiang Province.China

- Contact Person: Ms. Cathy

- Tel: 86-574-62233388

Premium Related Products

Other Products

Hot Products

Twin Screw Extruder Machine for 3D Printer Filament MaterialsNylon Extruder Machine with Air Cooling Hot Face Pelletizing SystemHigh Filler Formulation Twin Screw ExtruderTsh-75/Se-180 Water Ring Pelletizing System Twin Screw ExtruderPP,PE,PS+starch/PE,EVA,ABS+carbon black filling masterbatch pelletizer extruderHigh quality and Standard Twin Screw Extruder Screw ElementHS high quality TSE-65 twin-screw parallel co-rotating extruderUnderwater Extrusion Line PVC Masterbatch Making MachinePET Plastic Recycled Granules For Pelletizer Extrusion LineHS series SP Two-stage Compounding Extruder Pelletizing SystemSHJ-65 Co-rotating Twin-screw Extrusion machinery for pelletizingPlastic Pelletizing Line Horizontal Water Ring Extrusion MachineryTSE-65D Co-rotating Twin Screw Extruder in Air-cooling Extrusion LinePlastic Recycling Compound Masterbatch Filler Machine PriceMini Plastic Masterbatch Granulator Single Screw Extruder MachineMini PPR Pipe Plastic Compound Extruder Machine For Sale Price